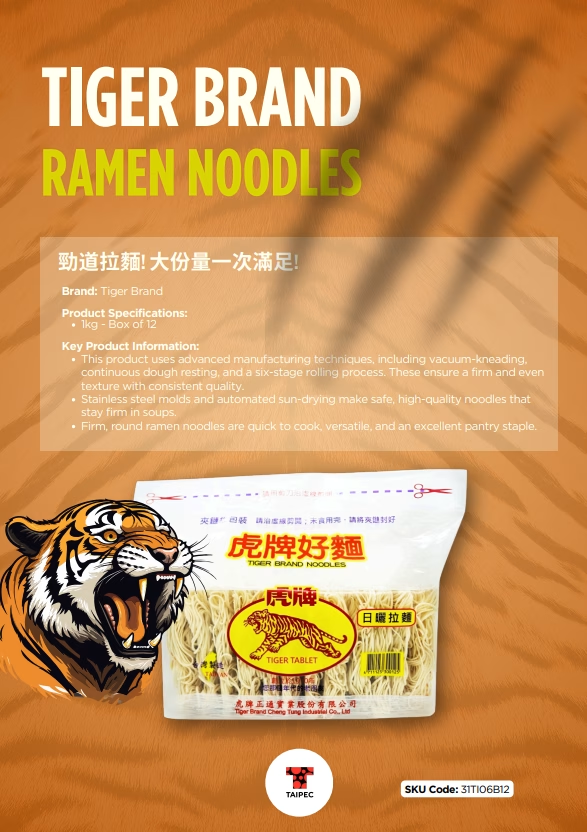

Tiger Brand – Ramen Noodles 1kg – Box of 10 – 30% Discount (BBD:2026-06-26)

Sale!

£49.30£39.44

Ready to cook

In stock

Description

- Vacuum Kneading: Air is first extracted before the dough is kneaded, reducing the presence of air molecules that can disrupt the firm texture of the noodles when formed.

- Continuous Dough Resting Machine: Traditionally, dough is flattened into long strips, rolled up, and placed in plastic bags to rest. The continuous dough resting machine reduces the chance of product contamination from reused plastic bags. It also ensures consistent resting times, preventing variations in product quality due to differing rest periods.

- Six-Stage Rolling Process: Mimicking traditional hand-rolling techniques, this automated process gradually flattens the dough in stages, from coarse to fine, to achieve the desired thickness. This ensures even distribution of water molecules throughout the dough.

- Stainless Steel Molds: Tiger Brand is one of the few noodle factories that use stainless steel molds, preventing plastic molds from breaking or chipping during the sun-drying and baking processes, which could contaminate the product.

- Automated Conveyor Belt Drying Line: The drying process is fully automated, with noodles transported to the top floor's sunlight drying and baking area via a conveyor belt. This reduces the risk of cross-contamination caused by manual handling. Every noodle passes through the same airflow and sunlight exposure, ensuring even temperature and consistent quality.

Specifications

Ingredients

WHEAT flour (90%), water, salt.

Allergens

| Contains Cereals Containing Gluten | Yes |

| Contains Milk | No |

| Contains Eggs | No |

| Contains Peanuts | No |

| Contains Nuts | No |

| Contains Crustaceans | No |

| Contains Mustard | No |

| Contains Fish | No |

| Contains Lupin | No |

| Contains Sesame | No |

| Contains Celery | No |

| Contains Soya | No |

| Contains Molluscs | No |

| Contains Sulphur Dioxide | No |

Other Dietary Information

| Suitable for Vegetarians | Yes |

| Suitable for Vegans | Yes |

Handling & Preparation

Directions for Use

See pack for details. Keep sealed after opening and use within 3 days.

Storage Instructions

Store in a cool, dry place out of direct sunlight.

Nutritional Information

| Typical Values Per 100g/ml | |

|---|---|

| Energy |

1519 kJ / 364 kcal |

| Fat | 1.9 g |

| - of which saturates | 0.3 g |

| Carbohydrate | 74 g |

| - of which sugars | 3.2 g |

| Protein | 13 g |

| Salt | 2 g |

Inner Component Details

| Weight/Volume: | |

| Inner Component GTIN: | 4711123300125 |

| Packaging Type: |

Product Packaging

| Product Name | Tiger Brand Ramen Noodles |

| Product Description | Tiger Brand Ramen Noodles, 1kg |

| Product Case Label Name | Tiger Brand Ramen Noodles, 1kg |

| Wholesale Traded Unit GTIN: | 4711123020016 |

Product Specification Last Updated (YYYY-MM-DD): 2025-01-07

Best Before Date

Best Before (DD/MM/YYYY): 26/06/2026